Whatsapp(Wechat):+86 137 8366 9139

- Corporation overview The heart of Bulletproof Industrial Vision & Philosophy Partnership Certifications Distribution Process

- Our service Global responsibility Maintenance and Service Examine Production Line Procurement Center Storage and Logistics Management

- Why Choose Bulletproof Industrial Production Base Services and Commitment Service Network

- Submersible Pumps QJ Deep Well Submersible Pump QS Small Submersible Electric Pump QJR Hot Water Well Submersible Pump 304 Stainless Steel Submersible Pump QJT Mine Submersible Pump QJG High Lift Submersible Pump Q Extra Big Submersible Pump QSP Fountain Submersible Pump QY Oil Filled Submersible Electric Pump QSZ(H) Axial Mixed Flow Submersible Pump

- Sewage Pumps WQ Non-Clogging Sewage Pump WQ Stainless Steel Sewage Pump WQS Water Filled Sewage Pump WQK Cutting Sewage Pump WQ Mine Sewage Pump WQB Black Non-Clogging Sewage Pump WQ-JY Automatic Mix Sewage Pump WQX D Type Bottom Suction Submersible Sewage Pump WQX H Black Project Sewage Pump

- Pipeline Pump ISW Type horizontal pipeline centrifugal pump ISG series single stage single suction vertical pipeline centrifugal pump IS/ISR/IY series single stage single suction centrifugal pump GDL series vertical multistage pipeline pump QDL/QDLF/CDL/CDLF Series light multistage centrifugal pump LG series vertical single-suction multistage sectional centrifugal pump LG-B series easy disassemble multistage high-level building water supply centrifugal pump

- Stainless Steel Submersible Pump 150QJ series submersible multistage electric well pump 125QJ series submersible multistage electric well pump 100QJ series submersible multistage electric well pump 90QJ series submersible multistage electric well pump 75QJ series submersible multistage electric well pump 6SP Stainless steel well submersible multistage electric pump 4SP stainless steel well submersible multistage electric pump Multifunction Control Cabinet SK series multifunction controller

- Diesel Engine Pump S/SH type single stage double suction axially split diesel engine pump D series horizontal multistage centrifugal diesel engine pump HW mixed flow volute diesel engine pump SN type horizontal double suction axially split diesel engine pump Mobile diesel engine water pump ZX, ZW series self-priming diesel engine pump Stationary horizontal centrifugal diesel engine pump D Type Pump DG Middle low pressure, sub-high-pressure multistage boiler water supply pump D/MD/DF series horizontal multistage centrifugal pump

- Split Centrifugal Pump OS Series single stage double suction split-case spiral centrifugal pump S/SH Series single stage double suction centrifugal pump SOW Series single stage double suction split-case centrifugal pump No Negative Pressure Water Supply Equipment WFY(G) Non-negative pressure boost pump stable water supply equipment WFY(W) Outdoor non-negative pressure boost pressure steady flow water supply equipment WFY(X) Box type non-negative pressure boost pressure steady flow water supply equipment

- YE3-IE3 three-phase high efficiency motor

- YE2-IE2 three-phase high efficiency motor

- YB3-IE3 three phase explosion-proof motor

- YB2 explosion proof three phase motor

- YX3 three phase high efficiency motor

- Y2 series three phase electric motor

- MS series three asynchronous motor

- Gost standard three phase motor

- YEJ2 Three Phase AC Induction Motor

- YVF2 series three phase electric motor

- YD series electric motor

- Y series electric motor

- YC series single phase electric motors

- YCL single phase electric motors

- YL series single phase electric motor

- YY series single phase electric motor

- MC aluminium frame single phase motor

- ML aluminium housing single phase motor

- MY aluminium housing single phase motor

- JY series single phase electric motor

- YZS series horizontal vibration motor

- YZO series electric vibrator motor

- YZD series electric vibrator motor

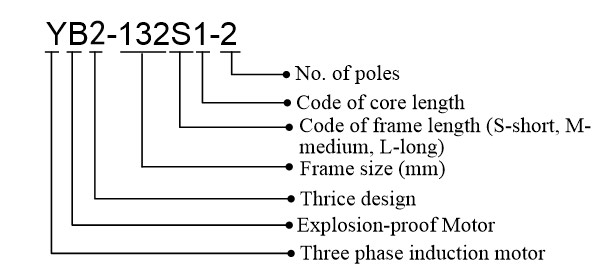

YB2 series explosion proof three phase motor

Protection class: IP55

Power: 0.55KW~450KW

Voltage: 380V, 660V, 1140V and 380V/660V, 660V/1140V/as required

Frequency: 50Hz/60Hz/as required

No. of Poles: 2, 4, 6, 8, 10, etc

Speed: 450rpm~3000rpm

YB2 series flameproof three phase asynchronous motor is the upgrading of the company YB series products is a basic series of explosion-proof motor. This series has the advantages of small size, light weight, beautiful appearance, safe and reliable operation, long life and excellent performance, installation and easy maintenance features.

This series of motor power rating, mounting dimensions conform to the standards of the International Electrotechnical Commission (IEC), the corresponding relationship with the German DIN42673 standard, the matching of the export of equipment and spare parts imported equipment.

This series motors are explosion-proof performance in line with GB3836.1-2000 "explosive gas atmospheres the electrical prepare Part 1: General requirements and GB3836.2-2000" explosive gas atmospheres - electrical equipment - Part 2: Flameproof "d" " shall also comply with IEC79-1, BS4683 and EN50018 requirements made of flameproof. The proof mark ExdI ExdIIAT4, ExdIIBT4 place with the presence of explosive gas mixtures.

ExdI apply to the explosive mixture of methane or coal dust coal mine mining face environment.

ExdIIAT4 for factory Class IIA, temperature class T1, T2, T3, and T4 group explosive gas mixture environment.

ExdIIBT4 for factory class IIB, temperature class T1, T2, T3, and T4 group explosive gas mixture environment.

Second, the Structure

The explosion-proof structure of the motor ExdI, ExdIIAT4, ExdIIBT4.The main motor enclosure protection rating of IP55.

Motor cooling method is IC410, IC411.

Motor insulation class F, the stator winding temperature margin, long life.

The motor has a cylindrical shaft, by coupling or spur gear transmission.

Motor stator windings of high-strength polyester enamelled round copper wire, and the VPI vacuum pressure impregnated, processing as an integrated whole, winding and insulation has good

Good electrical, mechanical, moisture resistance and thermal stability.

Motor rotor with cast aluminum structure, the parity of the rotor by balancing the motor running smoothly, small vibration, low noise.

Given motor, the rotor plate with high permeability, low-loss high-quality electrical steel, motor, low loss, high efficiency.

Bearing motors use low vibration, low noise bearings, frame size 132 and below, double sealed bearings, shaft end with a wave spring washer to moderate Beat rely on bearings, effectively inhibited the vibration and noise generated when the motor running; frame size 160 and above, the inner and outer cover structure, and the bearing parts of the ring axial fixation to prevent axial movement of the motor rotor.

To make the motor safe and reliable operation, the frame size 180 and above motor bearing structure set Note row of oil installations, frame size 250 and above, motors, and reserved the position of the bearing temperature monitoring sensor.

Third, the conditions of use

Rated voltage: 380V, 660V, 380/660V.

Rated frequency: 50Hz.

Fixed: continuous duty S1

Motor using the environmental conditions:

The altitude does not exceed 1000m, ambient air temperature changes with the seasons, for the indoor environment of -20 ℃ ~ +40 ℃.

|

Model |

Output |

Speed |

Rated Current |

Rated Torque |

Efficiency η |

Power Factor |

Locked-rotor Current/ |

Locked-rotor Torque/ |

Max. Torque/ |

Noise (dB(A)) |

Moment of Inertia |

|

YB2-80M1-2 |

0.75 |

2825 |

1.77 |

2.54 |

77.5 |

0.83 |

6.8 |

2.3 |

2.3 |

67 |

0.005 |

|

YB2-80M2-2 |

1.1 |

2826 |

2.43 |

3.72 |

82.8 |

0.83 |

7.3 |

2.3 |

2.3 |

67 |

0.007 |

|

YB2-90S-2 |

1.5 |

2840 |

3.23 |

5.04 |

84.1 |

0.84 |

7.6 |

2.3 |

2.3 |

72 |

0.009 |

|

YB2-90L-2 |

2.2 |

2840 |

4.59 |

7.4 |

85.6 |

0.85 |

7.8 |

2.3 |

2.3 |

72 |

0.017 |

|

YB2-100L-2 |

3 |

2880 |

6.04 |

9.95 |

86.7 |

0.87 |

8.1 |

2.3 |

2.3 |

76 |

0.03 |

|

YB2-112M-2 |

4 |

2890 |

8.03 |

13.22 |

87.6 |

0.88 |

8.3 |

2.3 |

2.3 |

77 |

0.063 |

|

YB2-132S1-2 |

5.5 |

2900 |

10.72 |

18.11 |

88.6 |

0.88 |

8 |

2.2 |

2.3 |

80 |

0.073 |

|

YB2-132S2-2 |

7.5 |

2900 |

14.31 |

24.7 |

89.5 |

0.89 |

7.8 |

2.2 |

2.3 |

80 |

0.21 |

|

YB2-160M1-2 |

11 |

2930 |

20.75 |

35.85 |

90.5 |

0.89 |

7.9 |

2.2 |

2.3 |

86 |

0.25 |

|

YB2-160M2-2 |

15 |

2930 |

28.05 |

48.89 |

91.3 |

0.89 |

8 |

2.2 |

2.3 |

86 |

0.31 |

|

YB2-160L-2 |

18.5 |

2930 |

34.4 |

60.3 |

91.8 |

0.89 |

8.1 |

2.2 |

2.3 |

86 |

0.37 |

|

YB2-180M-2 |

22 |

2940 |

40.74 |

71.46 |

92.2 |

0.89 |

8.2 |

2.2 |

2.3 |

88 |

0.63 |

|

YB2-200L1-2 |

30 |

2950 |

55.13 |

97.12 |

92.9 |

0.89 |

7.5 |

2.2 |

2.3 |

90 |

0.73 |

|

YB2-200L2-2 |

37 |

2950 |

67.7 |

119.78 |

93.3 |

0.89 |

7.5 |

2.2 |

2.3 |

90 |

1.28 |

|

YB2-225M-2 |

45 |

2970 |

81.98 |

144.7 |

93.7 |

0.89 |

7.6 |

2.2 |

2.3 |

92 |

1.55 |

|

YB2-250M-2 |

55 |

2970 |

99.88 |

176.85 |

94 |

0.89 |

7.6 |

2.2 |

2.3 |

93 |

1.89 |

|

YB2-280S-2 |

75 |

2970 |

135.34 |

241.16 |

94.6 |

0.89 |

6.9 |

2 |

2.3 |

94 |

2.02 |

|

YB2-280M-2 |

90 |

2970 |

161.72 |

289.39 |

95 |

0.89 |

7 |

2 |

2.3 |

94 |

2.26 |

|

YB2-315S-2 |

110 |

2980 |

195.47 |

352.52 |

95 |

0.9 |

7.1 |

2 |

2.2 |

96 |

2.42 |

|

YB2-315M-2 |

132 |

2980 |

233.58 |

423.02 |

95.4 |

0.9 |

7.1 |

2 |

2.2 |

96 |

2.73 |

|

YB2-315L-2 |

160 |

2980 |

280.01 |

512.75 |

95.4 |

0.91 |

7.1 |

2 |

2.2 |

98 |

3.22 |

|

YB2-315L1-2 |

185 |

2980 |

323.76 |

592.87 |

95.4 |

0.91 |

7.1 |

2 |

2.2 |

98 |

3.41 |

|

YB2-315L2-2 |

200 |

2980 |

350.01 |

640.94 |

95.4 |

0.91 |

7.1 |

2 |

2.2 |

98 |

3.86 |

|

YB2-80M1-4 |

0.55 |

1390 |

1.38 |

3.78 |

80.7 |

0.75 |

6.3 |

2.3 |

2.3 |

58 |

0.007 |

|

YB2-80M2-4 |

0.75 |

1390 |

1.85 |

5.15 |

82.3 |

0.75 |

6.5 |

2.3 |

2.3 |

58 |

0.012 |

|

YB2-90S-4 |

1.1 |

1400 |

2.66 |

7.5 |

83.8 |

0.75 |

6.6 |

2.3 |

2.3 |

61 |

0.015 |

|

YB2-90L-4 |

1.5 |

1400 |

3.75 |

10.23 |

85 |

0.75 |

6.9 |

2.3 |

2.3 |

61 |

0.031 |

|

YB2-100L-4 |

2.2 |

1420 |

4.78 |

14.8 |

86.4 |

0.81 |

7.5 |

2.3 |

2.3 |

64 |

0.039 |

|

YB2-100L2-4 |

3 |

1420 |

6.36 |

20.18 |

87.4 |

0.82 |

7.6 |

2.3 |

2.3 |

64 |

0.059 |

|

YB2-112M-4 |

4 |

1440 |

8.39 |

26.53 |

88.3 |

0.82 |

7.7 |

2.3 |

2.3 |

65 |

0.113 |

|

YB2-132S-4 |

5.5 |

1440 |

11.42 |

36.48 |

89.2 |

0.82 |

7.5 |

2 |

2.3 |

71 |

0.167 |

|

YB2-132M-4 |

7.5 |

1440 |

15.24 |

49.74 |

90.1 |

0.83 |

7.4 |

2 |

2.3 |

71 |

0.36 |

|

YB2-160M-4 |

11 |

1460 |

21.61 |

71.95 |

91 |

0.85 |

7.5 |

2.2 |

2.3 |

75 |

0.42 |

|

YB2-160L-4 |

15 |

1460 |

28.87 |

98.12 |

91.8 |

0.86 |

7.5 |

2.2 |

2.3 |

75 |

0.68 |

|

YB2-180M-4 |

18.5 |

1470 |

35.45 |

120.19 |

92.2 |

0.86 |

7.7 |

2.2 |

2.3 |

76 |

0.72 |

|

YB2-180L-4 |

22 |

1470 |

41.97 |

142.93 |

92.6 |

0.86 |

7.8 |

2.2 |

2.3 |

76 |

0.88 |

|

YB2-200L-4 |

30 |

1470 |

56.87 |

194.9 |

93.2 |

0.86 |

7.2 |

2.2 |

2.3 |

79 |

1.21 |

|

YB2-225S-4 |

37 |

1480 |

69.83 |

238.75 |

93.6 |

0.86 |

7.3 |

2.2 |

2.3 |

81 |

1.85 |

|

YB2-225M-4 |

45 |

1480 |

84.66 |

290.37 |

93.9 |

0.86 |

7.4 |

2.2 |

2.3 |

81 |

2.32 |

|

YB2-250M-4 |

55 |

1480 |

103.15 |

354.9 |

94.2 |

0.86 |

7.4 |

2.2 |

2.3 |

83 |

2.86 |

|

YB2-280S-4 |

75 |

1480 |

136.73 |

483.95 |

94.7 |

0.88 |

6.7 |

2.2 |

2.3 |

86 |

3.34 |

|

YB2-280M-4 |

90 |

1485 |

163.56 |

578.79 |

95 |

0.88 |

6.9 |

2.2 |

2.3 |

86 |

4.68 |

|

YB2-315S-4 |

110 |

1485 |

199.07 |

707.41 |

95.4 |

0.88 |

6.9 |

2.2 |

2.2 |

93 |

4.96 |

|

YB2-315M-4 |

132 |

1485 |

238.88 |

848.89 |

95.4 |

0.88 |

6.9 |

2.2 |

2.2 |

93 |

5.22 |

|

YB2-315L-4 |

160 |

1485 |

286.3 |

1028.96 |

95.4 |

0.89 |

6.9 |

2.2 |

2.2 |

94 |

5.43 |

|

YB2-315L1-4 |

185 |

1485 |

331.04 |

1189.61 |

95.4 |

0.89 |

6.9 |

2.2 |

2.2 |

94 |

5.62 |

|

YB2-315L2-4 |

200 |

1485 |

357.88 |

1286.2 |

95.4 |

0.89 |

6.9 |

2.2 |

2.2 |

94 |

6.45 |

|

YB2-80M2-6 |

0.55 |

910 |

1.54 |

5.77 |

75.4 |

0.72 |

4.7 |

1.9 |

2.1 |

54 |

0.059 |

|

YB2-90S-6 |

0.75 |

910 |

2.04 |

7.87 |

77.7 |

0.72 |

5.8 |

2.1 |

2.1 |

57 |

0.113 |

|

YB2-90L-6 |

1.1 |

910 |

2.87 |

11.54 |

79.9 |

0.73 |

5.9 |

2.1 |

2.1 |

57 |

0.167 |

|

YB2-100L-6 |

1.5 |

940 |

3.78 |

15.24 |

81.5 |

0.74 |

6 |

2.1 |

2.1 |

61 |

0.36 |

|

YB2-112M-6 |

2.2 |

940 |

5.42 |

22.35 |

83.4 |

0.74 |

6 |

2.1 |

2.1 |

65 |

0.42 |

|

YB2-132S-6 |

3 |

960 |

7.25 |

29.84 |

84.9 |

0.74 |

6.2 |

2 |

2.1 |

69 |

0.68 |

|

YB2-132M1-6 |

4 |

960 |

9.54 |

39.79 |

86.1 |

0.74 |

6.8 |

2 |

2.1 |

69 |

0.72 |

|

YB2-132M2-6 |

5.5 |

960 |

12.75 |

54.71 |

87.4 |

0.75 |

7.1 |

2 |

2.1 |

69 |

0.81 |

|

YB2-160M-6 |

7.5 |

970 |

16.41 |

73.84 |

89 |

0.78 |

6.7 |

2.1 |

2.1 |

73 |

1.21 |

|

YB2-160L-6 |

11 |

970 |

23.51 |

108.3 |

90 |

0.79 |

6.9 |

2.1 |

2.1 |

73 |

1.32 |

|

YB2-180L-6 |

15 |

970 |

30.92 |

147.68 |

91 |

0.81 |

7.2 |

2 |

2.1 |

73 |

1.62 |

|

YB2-200L1-6 |

18.5 |

970 |

37.92 |

182.14 |

91.5 |

0.81 |

7.2 |

2.1 |

2.1 |

76 |

1.84 |

|

YB2-200L2-6 |

22 |

970 |

44.31 |

216.6 |

92 |

0.82 |

7.3 |

2.1 |

2.1 |

76 |

2.43 |

|

YB2-225M-6 |

30 |

980 |

60.83 |

292.35 |

92.5 |

0.81 |

7.1 |

2 |

2.1 |

76 |

2.68 |

|

YB2-250M-6 |

37 |

980 |

71.96 |

360.56 |

93 |

0.84 |

7.1 |

2.1 |

2.1 |

78 |

3.46 |

|

YB2-280S-6 |

45 |

980 |

85.02 |

438.52 |

93.5 |

0.86 |

7.2 |

2.1 |

2 |

80 |

3.97 |

|

YB2-280M-6 |

55 |

980 |

103.59 |

535.97 |

93.8 |

0.86 |

7.2 |

2.1 |

2 |

80 |

4.57 |

|

YB2-315S-6 |

75 |

985 |

142.31 |

727.16 |

94.2 |

0.85 |

6.7 |

2 |

2 |

85 |

4.83 |

|

YB2-315M-6 |

90 |

985 |

168.25 |

872.59 |

94.5 |

0.84 |

6.7 |

2 |

2 |

85 |

5.32 |

|

YB2-315L1-6 |

110 |

985 |

206.96 |

1066.5 |

95 |

0.85 |

6.7 |

2 |

2 |

85 |

5.95 |

|

YB2-315L2-6 |

132 |

985 |

245.47 |

1279.8 |

95 |

0.86 |

6.7 |

2 |

2 |

85 |

7.32 |

|

YB2-90L-8 |

0.55 |

710 |

2.07 |

7.4 |

63 |

0.61 |

4 |

1.8 |

2 |

56 |

0.22 |

|

YB2-100L-8 |

0.75 |

710 |

2.36 |

10.09 |

70 |

0.67 |

4 |

1.8 |

2 |

59 |

0.24 |

|

YB2-100L2-8 |

1.1 |

710 |

3.32 |

14.8 |

72 |

0.69 |

5 |

1.8 |

2 |

59 |

0.25 |

|

YB2-112M-8 |

1.5 |

710 |

4.4 |

20.18 |

74 |

0.7 |

5 |

1.8 |

2 |

61 |

0.28 |

|

YB2-132S-8 |

2.2 |

710 |

5.8 |

29.59 |

79 |

0.71 |

6 |

1.8 |

2 |

64 |

0.3 |

|

YB2-132M-8 |

3 |

710 |

7.71 |

40.35 |

80 |

0.73 |

6 |

1.8 |

2 |

64 |

0.32 |

|

YB2-160M1-8 |

4 |

720 |

10.28 |

53.06 |

81 |

0.73 |

6 |

1.9 |

2 |

68 |

0.46 |

|

YB2-160M2-8 |

5.5 |

720 |

13.24 |

72.95 |

83 |

0.74 |

6 |

1.9 |

2 |

68 |

0.61 |

|

YB2-160L-8 |

7.5 |

720 |

17.64 |

99.48 |

85.5 |

0.75 |

6 |

1.9 |

2 |

68 |

1.06 |

|

YB2-180L-8 |

11 |

730 |

25.28 |

143.9 |

87.5 |

0.75 |

6.5 |

2 |

2 |

70 |

1.6 |

|

YB2-200L-8 |

15 |

730 |

33.69 |

196.23 |

88 |

0.76 |

6.6 |

2 |

2 |

73 |

2.28 |

|

YB2-225S-8 |

18.5 |

730 |

40.04 |

242.02 |

90 |

0.76 |

6.6 |

1.9 |

2 |

73 |

2.74 |

|

YB2-225M-8 |

22 |

730 |

47.35 |

287.81 |

90.5 |

0.78 |

6.6 |

1.9 |

2 |

73 |

3.67 |

|

YB2-250M-8 |

30 |

730 |

63.4 |

392.47 |

91 |

0.79 |

6.5 |

1.9 |

2 |

75 |

5.16 |

|

YB2-280S-8 |

37 |

740 |

77.77 |

477.5 |

91.5 |

0.79 |

6.6 |

1.9 |

2 |

76 |

5.82 |

|

YB2-280M-8 |

45 |

740 |

94.07 |

580.74 |

92 |

0.79 |

6.6 |

1.9 |

2 |

76 |

6.74 |

|

YB2-315S-8 |

55 |

740 |

111.17 |

709.8 |

92.8 |

0.81 |

6.6 |

1.8 |

2 |

82 |

7.35 |

|

YB2-315M-8 |

75 |

740 |

150.46 |

967.91 |

93.5 |

0.81 |

6.2 |

1.8 |

2 |

82 |

8.79 |

|

YB2-315L1-8 |

90 |

740 |

177.77 |

1161.49 |

93.8 |

0.82 |

6.4 |

1.8 |

2 |

82 |

9.18 |

|

YB2-315L2-8 |

110 |

740 |

216.82 |

1419.59 |

94 |

0.82 |

6.4 |

1.8 |

2 |

82 |

10.19 |

|

YB2-315S-10 |

45 |

587 |

99.63 |

732.11 |

91.5 |

0.75 |

6.2 |

1.5 |

2 |

82 |

7.35 |

|

YB2-315M-10 |

55 |

587 |

121.11 |

894.8 |

92 |

0.75 |

6.2 |

1.5 |

2 |

82 |

8.79 |

|

YB2-315L1-10 |

75 |

587 |

162.09 |

1220.19 |

92.5 |

0.76 |

5.8 |

1.5 |

2 |

82 |

9.18 |

|

YB2-315L2-10 |

90 |

587 |

190.95 |

1464.22 |

93 |

0.77 |

5.9 |

1.5 |

2 |

82 |

10.19 |

|

YB2-250M-12 |

18.5 |

480 |

47.67 |

368.07 |

88 |

0.67 |

5.5 |

1.2 |

2 |

75 |

5.16 |

|

YB2-280S-12 |

22 |

480 |

55.05 |

437.71 |

88 |

0.69 |

5.5 |

1.2 |

2 |

85 |

5.82 |

|

YB2-280M-12 |

30 |

480 |

71.13 |

596.88 |

89 |

0.72 |

5.5 |

1.2 |

2 |

85 |

6.74 |

|

YB2-315S-12 |

37 |

480 |

84.86 |

728.56 |

92 |

0.72 |

6.5 |

1.2 |

2 |

86 |

7.35 |

|

YB2-315M-12 |

45 |

480 |

103.21 |

886.08 |

92 |

0.72 |

6.5 |

1.2 |

2 |

89 |

8.79 |

|

YB2-315L1-12 |

55 |

480 |

124.42 |

1028.99 |

92 |

0.73 |

6.5 |

1.2 |

2 |

89 |

9.18 |

|

YB2-315L2-12 |

75 |

480 |

167.84 |

1476.8 |

93 |

0.73 |

6.5 |

1.2 |

2 |

92 |

10.19 |

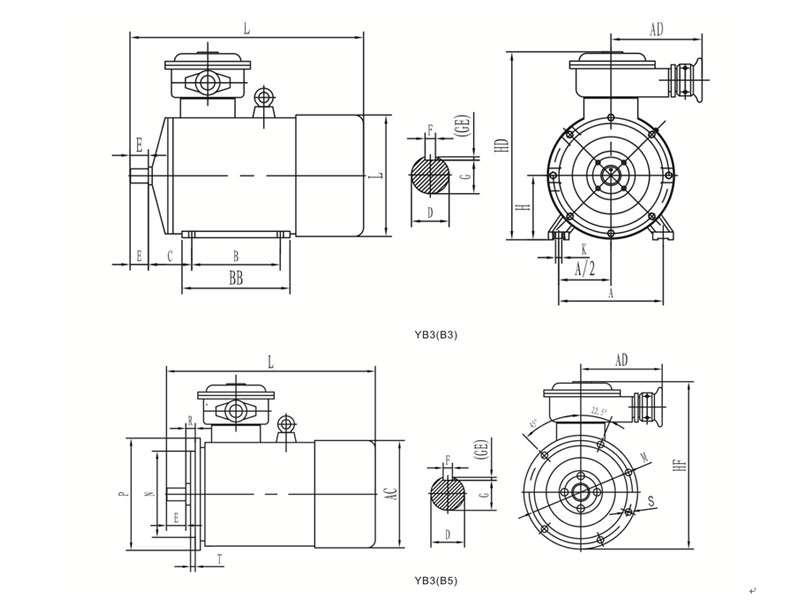

The Frame Size and Mounting Dimensions of YB3 Series

|

Frame Size |

No. of Poles |

Frame Dimension (mm) |

Shaft Extension (mm) |

AB |

AC |

AD |

HD |

L |

BB |

||||||||

|

A |

A/2 |

B |

C |

H |

K |

D |

E |

F |

G |

||||||||

|

100L |

2.4.6 |

160 |

80 |

140 |

63 |

100 |

12 |

28 |

60 |

8 |

24 |

200 |

202 |

180 |

345 |

448 |

180 |

|

112M |

2.4.6 |

190 |

95 |

140 |

70 |

112 |

12 |

28 |

60 |

8 |

24 |

245 |

224 |

195 |

360 |

500 |

180 |

|

132S |

2.4.6.8 |

216 |

108 |

140 |

89 |

132 |

12 |

38 |

80 |

10 |

33 |

280 |

264 |

280 |

420 |

550 |

190 |

|

132M |

2.4.6.8 |

216 |

108 |

178 |

89 |

132 |

15 |

38 |

80 |

10 |

33 |

280 |

264 |

280 |

420 |

660 |

230 |

|

160M |

2.4.6.8 |

254 |

127 |

210 |

108 |

160 |

15 |

42 |

110 |

12 |

37 |

330 |

330 |

208 |

485 |

720 |

260 |

|

160L |

2.4.6.8 |

254 |

127 |

254 |

108 |

160 |

15 |

42 |

110 |

12 |

37 |

330 |

330 |

208 |

485 |

750 |

310 |

|

180M |

2.4.6.8 |

279 |

139.5 |

241 |

121 |

180 |

15 |

48 |

110 |

14 |

42.5 |

355 |

350 |

202 |

525 |

771 |

340 |

|

180L |

2.4.6.8 |

279 |

139.5 |

279 |

121 |

180 |

19 |

48 |

110 |

14 |

42.5 |

355 |

350 |

202 |

525 |

791 |

340 |

|

200L |

2.4.6.8 |

318 |

159 |

305 |

133 |

200 |

19 |

55 |

110 |

16 |

49 |

390 |

390 |

250 |

645 |

840 |

370 |

|

225S |

4.8 |

356 |

178 |

286 |

149 |

225 |

19 |

60 |

140 |

18 |

53 |

435 |

436 |

250 |

690 |

888 |

380 |

|

225M |

2 |

356 |

178 |

311 |

149 |

225 |

19 |

55 |

110 |

16 |

49 |

435 |

436 |

250 |

690 |

918 |

355 |

|

225M |

4.6.8 |

356 |

178 |

311 |

149 |

225 |

19 |

60 |

140 |

18 |

53 |

435 |

436 |

250 |

690 |

918 |

355 |

|

250M |

2 |

406 |

203 |

349 |

168 |

250 |

24 |

60 |

140 |

18 |

53 |

490 |

488 |

275 |

720 |

965 |

420 |

|

250M |

4.6.8 |

406 |

203 |

349 |

168 |

250 |

24 |

65 |

140 |

18 |

58 |

490 |

488 |

275 |

720 |

965 |

420 |

|

280S |

2 |

457 |

228.5 |

368 |

190 |

280 |

24 |

65 |

140 |

18 |

58 |

545 |

550 |

275 |

790 |

1007 |

445 |

|

280S |

4.6.8 |

457 |

228.5 |

368 |

190 |

280 |

24 |

75 |

140 |

20 |

67.5 |

545 |

550 |

275 |

790 |

1007 |

445 |

|

280M |

2 |

457 |

228.5 |

419 |

190 |

280 |

24 |

65 |

140 |

18 |

58 |

545 |

550 |

275 |

790 |

1072 |

500 |

|

280M |

4.6.8 |

457 |

228.5 |

419 |

190 |

280 |

24 |

75 |

140 |

20 |

67.5 |

545 |

550 |

275 |

790 |

1072 |

500 |

|

315S |

2 |

508 |

254 |

406 |

216 |

315 |

28 |

65 |

140 |

18 |

58 |

628 |

613 |

320 |

960 |

1185 |

550 |

|

315S |

4.6.8.10 |

508 |

254 |

406 |

216 |

315 |

28 |

80 |

170 |

22 |

71 |

628 |

613 |

320 |

960 |

1260 |

550 |

|

315M |

2 |

508 |

254 |

457 |

216 |

315 |

28 |

65 |

140 |

18 |

58 |

628 |

613 |

320 |

960 |

1305 |

680 |

|

315M |

4.6.8.10 |

508 |

254 |

457 |

216 |

315 |

28 |

80 |

170 |

22 |

71 |

628 |

613 |

320 |

960 |

1280 |

680 |

|

315L |

2 |

508 |

254 |

508 |

216 |

315 |

28 |

65 |

140 |

18 |

58 |

628 |

613 |

320 |

960 |

1305 |

680 |

|

315L |

4.6.8.10 |

508 |

254 |

508 |

216 |

315 |

28 |

80 |

170 |

22 |

71 |

628 |

613 |

320 |

960 |

1280 |

680 |

here

for

price

We will contact with you within 8 hours